Contact Us to Place an Order

Fill out the form below to contact us or call (818) 365-9561 to place an order.

Our Products

Discover what we can provide for you.

We Can Help!

Find Out How We Can Help You Meet and Exceed Subcontracting Goals

Ready to Order? Call Us to Place Your Order:

(818) 365-9561

Meet Our Partners

Being a leader in industry is not a singular feat. We are proud to be affiliated with the following organizations:

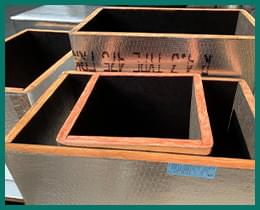

CASCO Quality In Every Product

What You Can Expect from Our Commercial HVAC Products:

- Multiple duct types and materials for your unique needs.

- Wide range of sheet metal fittings.

- Critical accessories for your HVAC installation projects.

- Industry-leading customer service and care.

Hear From Our Customers

What CASCO Customers Have to Say About Our Products.

Casco Provides the Best Commercial HVAC Supplies in the Industry.

Contact Us Today to Learn More or Place an Order